Enhancing Product Appearances: The Function of In-Mold Decorations in Production

Enhancing Product Appearances: The Function of In-Mold Decorations in Production

Blog Article

Understanding In-Mold Decorations: Techniques, Patterns, and Ideal Practices for Ideal Results

In the realm of production, the art of in-mold designs stands as a crucial element of item layout and manufacturing. As industries continuously look for ingenious ways to boost visual charm and capability, mastering the complexities of in-mold decors has become a crucial ability. From selecting the appropriate products to integrating cutting-edge design trends, the journey towards achieving optimum cause this domain is multifaceted. By delving right into the techniques, trends, and best practices that underpin successful in-mold design processes, organizations can unlock a realm of opportunities that not only boost the aesthetic attraction of their products but likewise simplify production efficiency and boost consumer engagement.

Material Choice

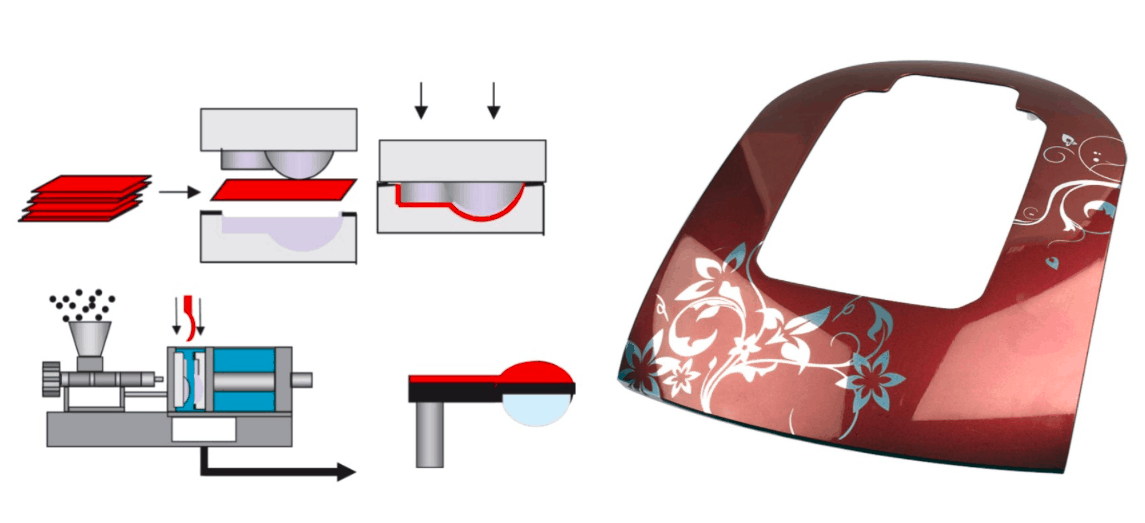

Material option is a critical aspect of understanding in-mold decorations, as it straight affects the high quality and toughness of the end product. When picking materials for in-mold designs, it is important to think about factors such as compatibility with the molding procedure, the desired visual outcome, and the ecological conditions the item will face. Polycarbonate products like polycarbonate, ABDOMINAL, and polypropylene are commonly utilized for in-mold decorations due to their versatility and capacity to attain complex styles. These materials use superb moldability, allowing makers to create complex forms and patterns with accuracy.

Additionally, the picked product ought to have good attachment buildings to guarantee that the design adheres firmly to the substrate throughout the molding procedure. Attachment in between the decor and the product is important for stopping delamination and making certain durable visual charm. Furthermore, materials with high heat resistance are liked for in-mold decors, particularly for items that will certainly be exposed to elevated temperature levels throughout their lifecycle. By thoroughly choosing the suitable product for in-mold decors, suppliers can improve the general high quality and resilience of their items, meeting the expectations of both clients and end-users.

Style Development

A crucial consider advancing the area of in-mold decors is the continual exploration and execution of layout development methods. Design innovation plays an important role in enhancing the aesthetic allure, performance, and total quality of products produced using in-mold decor procedures. By including cutting-edge design aspects, makers can separate their products in the market, attract consumers, and stay ahead of competitors.

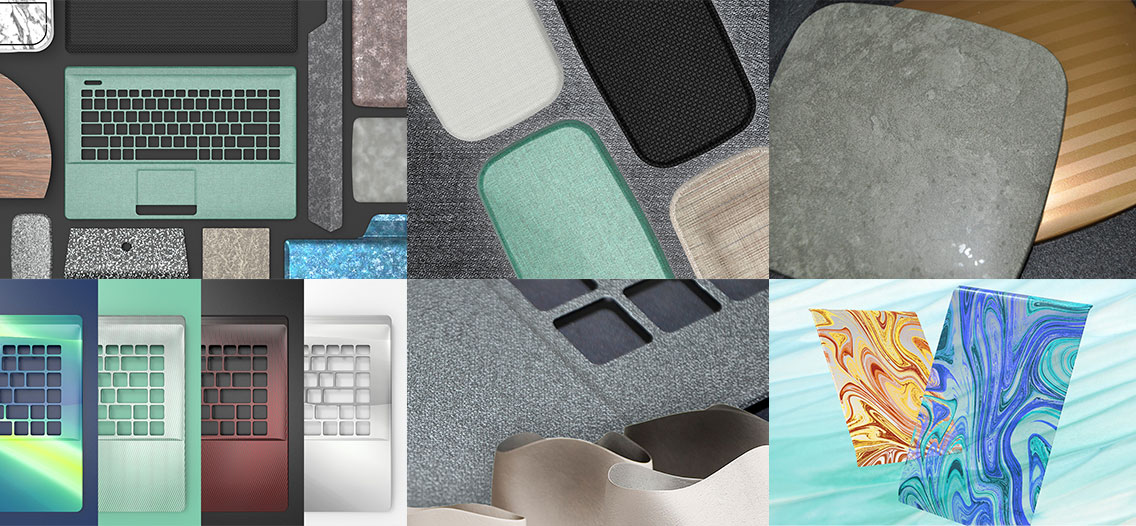

One of the key aspects of layout innovation in in-mold decorations is the integration of elaborate patterns, structures, and graphics that were formerly challenging to accomplish with conventional decoration methods. Advanced modern technologies such as 3D printing and digital layout tools make it possible for designers to produce complicated and detailed styles that can be seamlessly moved onto shaped components. Furthermore, the use of dynamic colors, metallic surfaces, and special results like gloss or matte appearances can additionally boost the visual charm of in-mold decorated products.

Furthermore, design technology extends beyond looks to incorporate useful improvements such as ergonomic forms, integrated attributes, and personalized aspects that accommodate specific customer requirements. By accepting style development, producers find more info can open new opportunities for creative thinking, customization, and product distinction in the affordable landscape of in-mold decors.

Manufacturing Performance

Efficient manufacturing processes are necessary for converting the innovative layouts developed in the field of in-mold decors into high-grade ended up items that fulfill market needs and customer expectations. In the world of in-mold decorations, manufacturing performance encompasses numerous crucial facets that add to the overall success of the manufacturing procedure. One crucial component is the optimization of mold design and tooling to ensure smooth and accurate design transfer onto the last product. By fine-tuning mold configurations and spending in top notch tooling products, producers can enhance effectiveness and uniformity in production.

Automation not only speeds up the production procedure but also enhances precision and repeatability, leading to an extra top notch and uniform end product. In general, a holistic strategy to production performance is extremely important in optimizing the capacity of in-mold design methods and achieving ideal outcomes in the competitive market landscape.

Quality Assurance Procedures

What are the crucial techniques for making certain rigorous top quality control steps in the world of in-mold designs? Quality control procedures are vital in in-mold decoration procedures to ensure the production of high-grade and remarkable ended up items.

Making use of sophisticated modern technologies such as automated assessment systems can additionally enhance the quality control process by offering trusted and accurate data for analysis. These systems can spot blemishes that might be missed by hands-on examinations, therefore enhancing total item quality and uniformity.

Normal training and development programs for employees included in the in-mold design procedure can additionally add to maintaining high-grade requirements. By educating personnel on best methods, top quality assumptions, and the value of interest to information, firms can foster a culture of high quality consciousness throughout the company.

Customer Allure

To enhance the marketability of in-mold decor products, catering and comprehending to consumer choices play a crucial duty in identifying their appeal and success. Consumer allure in in-mold decorations is affected by numerous aspects, including design aesthetic appeals, shade choices, sturdiness, and total functionality. Customers are increasingly looking for individualized and special items that mirror their uniqueness and style. Consequently, offering customization choices such as individualized designs, color variations, and textural components can substantially boost the allure of in-mold decor products.

Verdict

In-mold decorations supply a flexible and efficient means to enhance item looks. By meticulously choosing materials, embracing innovative designs, optimizing production procedures, implementing quality control actions, and prioritizing customer allure, makers can attain ideal results. It is critical for business to continuously adapt and improve their methods to stay competitive out there. In-Mold Decorations. Understanding in-mold decorations requires an alternative approach that takes into consideration all elements of the manufacturing procedure to ensure success.

In the world of production, the art of in-mold check this site out decorations stands as a critical element of product design and manufacturing. Style innovation plays a critical function in enhancing the aesthetic charm, performance, and total top quality of products made using in-mold decor processes.One of the vital elements of style technology in in-mold decors is the combination of elaborate patterns, structures, and graphics that were previously challenging to attain with conventional decoration approaches.Reliable manufacturing processes are crucial for equating the cutting-edge styles developed in the field of in-mold decors right into top quality finished products that fulfill market demands and customer expectations. Using personalization options such as personalized styles, color variants, and textural components can dramatically enhance the appeal of in-mold design products.

Report this page